Печи для спекания зубов

Стоматологические печи для спекания используются для изготовления прочных и точных зубных протезов (таких как коронки, мосты, абатменты для имплантатов и виниры) путем спекания основных материалов (диоксида циркония, титановых сплавов, стеклокерамики). Они повышают прочность, биосовместимость и прилегание материалов, служат для стоматологических клиник, лабораторий и научно-исследовательских работ.

- Используйте высококачественное сырье

- Быстрая доставка по умолчанию DHL

- 30-дневный беззаботный возврат и обмен

- Профессиональное обслуживание клиентов

Печь для спекания с быстрой и медленной интеграцией Jeedent

Smart Touch:Интерфейс управления представляет собой 7-дюймовый сенсорный ЖК-дисплей высокой четкости с графическим отображением и простым управлением.

Быстрое и медленное интегрированное спекание:печь сохранения тепла из импортного сырья оснащена 1850 кремний-молибденовыми стержнями высокой степени очистки

Экологически чистые и не загрязняющие окружающую среду:Сердечник высокотемпературной печи изготовлен из импортного глиноземистого легкого волокнистого материала, который обладает отличными теплоизоляционными характеристиками, экологически чист и не загрязняет окружающую среду

Точный контроль температуры:Импортный интеллектуальный ПИД-регулятор температуры, высокая точность регулирования температуры, надежная работа

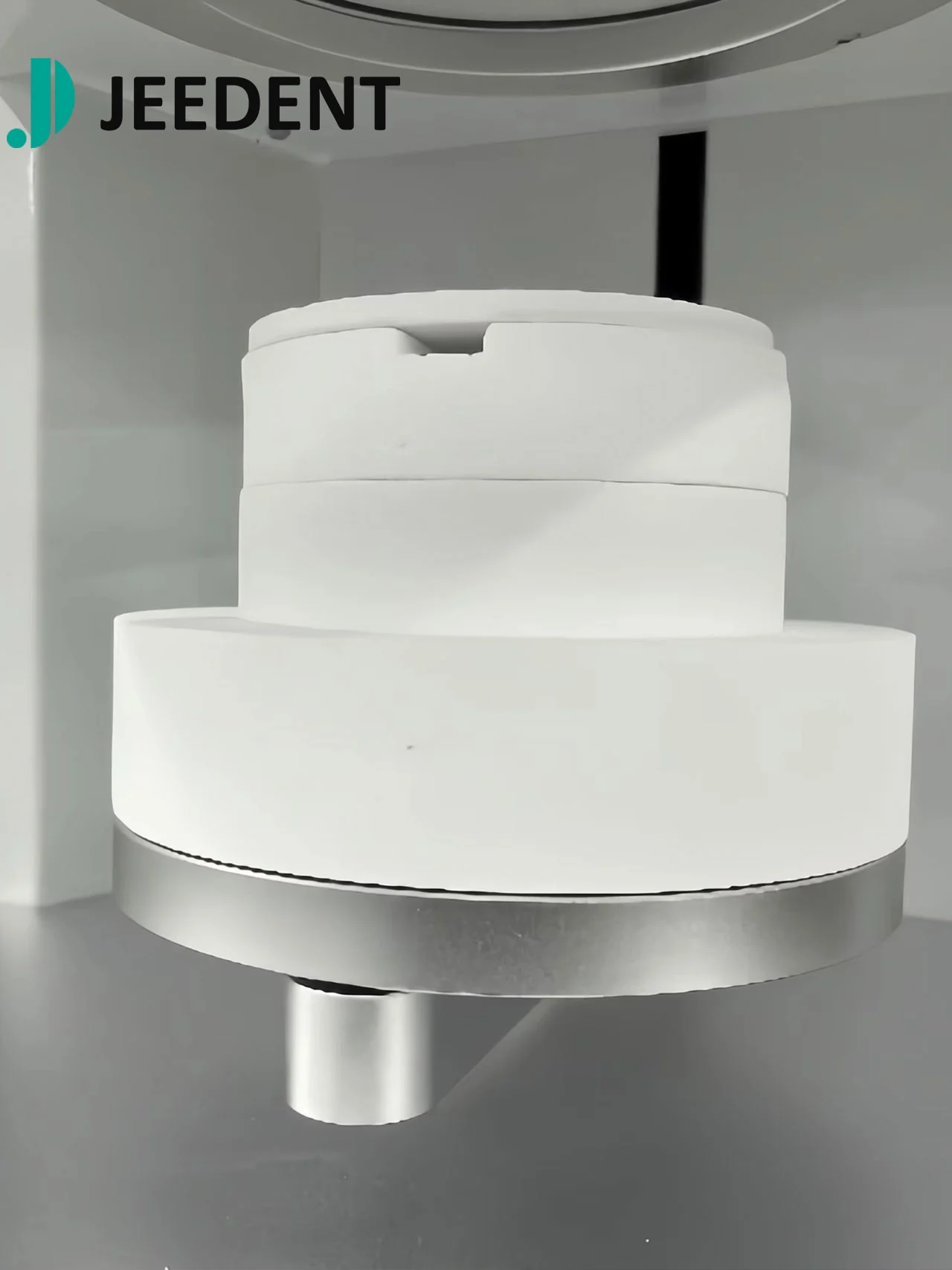

Отображение продукта

Стоматологические печи для спекания имеют решающее значение для изготовления зубных протезов. В них используется точный высокотемпературный контроль для спекания таких материалов, как диоксид циркония, глинозем, титановые сплавы и стеклокерамика.

| Встроенная печь для быстрого и медленного спекания Технические параметры |

|||

| Технические характеристики | Параметры | Технические характеристики | Параметры |

| Размер | 370*530*780 мм | Тип отопления | Быстро и медленно |

| Вес | 50 КГ | Количество программ | 24 |

| Размер печи | Диаметр 110м*130мм | Точность управления | ±1℃ |

| Размер сенсорного экрана | 7“ True Color | Источник питания | AC220V/50HZ |

| Нормальная температура спекания | 1500℃~1550℃ | Номинальная мощность | ≤2KW |

| Скорость нагрева | 30℃/мин | Максимальная допустимая температура | 1600℃ |

| Самое быстрое время спекания | Прорезывание зубов 90 минут | Количество нагревательных стержней | 4 шт (стержни из молибдена с кремнием) |

Основные преимущества

✅ Улучшение характеристик материала: Повышение прочности, износостойкости и биосовместимости за счет устранения пор/загрязнений; обеспечение долгосрочной безопасности в полости рта.

✅Обеспечивают точность: Температурный контроль ±1℃ и настраиваемая атмосфера (воздух, вакуум, инертный газ) позволяют предсказуемо уменьшить усадку материала для точного и плотного прилегания реставраций.

✅ Универсальная совместимость: Работают с большинством стоматологических материалов (керамика, металлы, композиты) для различных типов реставраций.

✅Повышение эффективности: Поддержка пакетной обработки, автоматические предустановленные программы и сокращение повторной обработки благодаря неизменному качеству.

✅ImpУдобство использования и безопасность: Компактные конструкции, интеллектуальные системы управления и функции безопасности подходят для использования в клинических/лабораторных условиях.

Ключевые приложения

✅Используется в стоматологических клиниках: В паре с CAD/CAM-системами для реставраций в один день (например, коронки из диоксида циркония), чтобы свести к минимуму визиты пациентов.

✅ Зуботехнические лаборатории: Массовое производство коронок, мостов и абатментов для имплантатов с использованием многоатмосферных моделей большой емкости.

✅ Восстановление имплантатов: Вакуумное спекание компонентов имплантатов из титана/титанового сплава для обеспечения биосовместимости и точности.

✅ Эстетические реставрации: Изготовление естественных передних реставраций (например, виниров) с контролируемым спеканием для оптимальной прозрачности и стабильности цвета.

✅Образование и НИОКР: возможность создания индивидуальных профилей спекания для исследования материалов и обучения студентов

1. Вопрос: Вы фабрика или торговая компания?

A: Мы являемся профессиональным производителем, в то же время у нас есть возможность организовать источник товаров. Мы также устанавливаем долгосрочные отношения сотрудничества с некоторыми известными брендами в стране и за рубежом.

2.Q: Как долго длится срок выполнения заказа?

A: Мы отправим товар немедленно, если у нас есть запас, большинство товаров требуют 5-7 рабочих дней в зависимости от заказанного количества. Если вам нужен срочный заказ, свяжитесь с нашими представителями, чтобы обсудить ваши конкретные потребности.

3.Q:Перед массовым заказом, вы можете предложить образцы? Как вы будете взимать плату за них?

A: Мы готовы предложить образцы, чтобы снизить риск покупки. Как правило, если из инвентаря, мы можем доставить в течение 3 дней, однако, если нужно обработки, мы можем доставить в течение 15 дней. Для некоторых сложных элементов, время доставки будет решаться его класса сложности. Для некоторых товаров с низкой стоимостью, мы можем предложить бесплатный образец, однако мы хотели бы, чтобы вы могли позволить себе стоимость перевозки. Для персонализированных продуктов, мы должны взимать стоимость разработки.

4.Q:Могу ли я настроить продукты?

A. Конечно, мы можем создать новую форму для производства продукции для вас. стоимость формы в зависимости от количества.

5.В:Что мы можем у вас купить?

A:Стоматологические блоки из диоксида циркония, стоматологический дисиликат лития, стоматологические сканеры, стоматологический фрезерный станок, стоматологическая печь для спекания и CAD/CAM машины Мы предоставляем универсальную покупку для дилеров стоматологических принадлежностей и стоматологических лабораторий в мире. Добро пожаловать, чтобы связаться со мной для нашего каталога продукции.

6.Q:Как ваша фабрика осуществляет контроль качества?

A: Мы строго следуем международным и отечественным медицинским стандартам. Инспекторы в разных позициях, включая упаковку, обеспечивают качество продукции. Если у вас есть проблемы в использовании, вы можете описать проблему подробно, мы попросим техника, чтобы дать вам решение.

7.В: Как сделать заказ в вашем магазине?

A: Шаг1 Отправить ваш запрос к нам.

Шаг 2 Мы предоставим вам цену в течение 24 часов.

Шаг 3 Договоритесь о цене.

Шаг 4 Организуйте оплату заказа.

Шаг 5 Выполните доставку в срок.

8.Q:Если качество не может удовлетворить требование или любые потери во время перевозки, как мы должны сделать?

A: У нас есть строгий тест QC и профессиональная команда QC. Мы всегда предлагаем квалифицированные продукты. Если что-то пойдет не так, качество не может удовлетворить требования по контракту, мы будем воспроизводить квалифицированные продукты или возвращать оплату. У нас есть профессиональная команда упаковки и будет упаковать продукт в безопасный пакет для доставки на большие расстояния. Если какие-либо потери во время перевозки, мы надеемся, что вы можете помочь нам претензии от логистической компании, и мы организуем замену соответственно.

Блоки из белого циркония

Блоки из белого циркония Многослойные блоки из диоксида циркония

Многослойные блоки из диоксида циркония Цветные циркониевые блоки

Цветные циркониевые блоки Блоки из диоксида циркония 3D

Блоки из диоксида циркония 3D Блоки из диоксида циркония 4D

Блоки из диоксида циркония 4D Янтарный дисиликат лития

Янтарный дисиликат лития Пресс фарфоровый

Пресс фарфоровый Неагломерированная керамика

Неагломерированная керамика C14 Литий-дисиликатная керамика

C14 Литий-дисиликатная керамика B40 Литий-дисиликатная керамика

B40 Литий-дисиликатная керамика Диск WAX

Диск WAX Титановый диск

Титановый диск Двухслойный диск из ПММА

Двухслойный диск из ПММА Диск из ПММА

Диск из ПММА PEEK Dics

PEEK Dics Фрезерные боры для стоматологии

Фрезерные боры для стоматологии Морилка и глазурь

Морилка и глазурь Паста для сканирования зубов

Паста для сканирования зубов Полировочная паста для зубов

Полировочная паста для зубов Паста для спекания зубов

Паста для спекания зубов Настольные стоматологические 3D-сканеры

Настольные стоматологические 3D-сканеры Интраоральный сканер

Интраоральный сканер Печи для спекания зубов

Печи для спекания зубов Печь для производства стоматологического фарфора

Печь для производства стоматологического фарфора Стоматологический фрезерный станок

Стоматологический фрезерный станок Набор для полировки зубов

Набор для полировки зубов Артикулятор BN

Артикулятор BN Полностью регулируемые артикуляторы

Полностью регулируемые артикуляторы