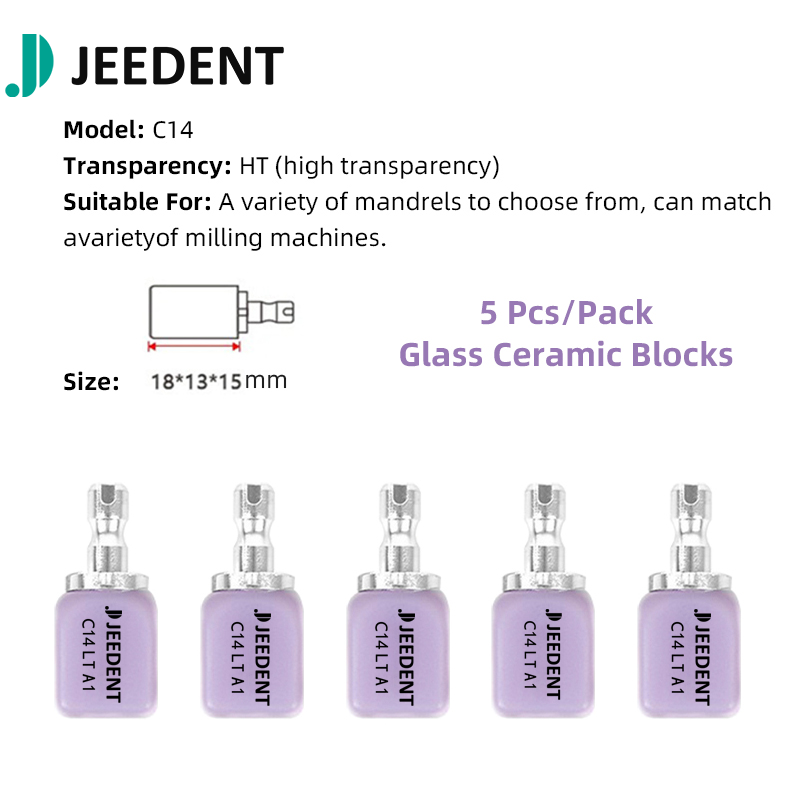

Lithium Disilicate Ceramics For CAD

Lithium Disilicate Ceramic is a globally popular digital chair side all-ceramic material, which is easy to mill and crystalization process only takes 20 minutes, with the CAD/CAM system of high efficiency.precise production process precisely matched, advanced to achieve instant restoration; superior transparency, presenting a highly bionic aesthetic effect.

- Use high-quality raw materials

- Fast delivery by default DHL or Fedex

- 30-day worry-free return and exchange

- Professional customer service

Lithium Disilicate Ceramics For CAD

Lithium Disilicate Ceramic is a globally popular digital chair side all-ceramic material, which is easy to mill and crystalization process only takes 20 minutes, with the CAD/CAM system of high efficiency.precise production process precisely matched, advanced to achieve instant restoration; superior transparency, presenting a highly bionic aesthetic effect.

-

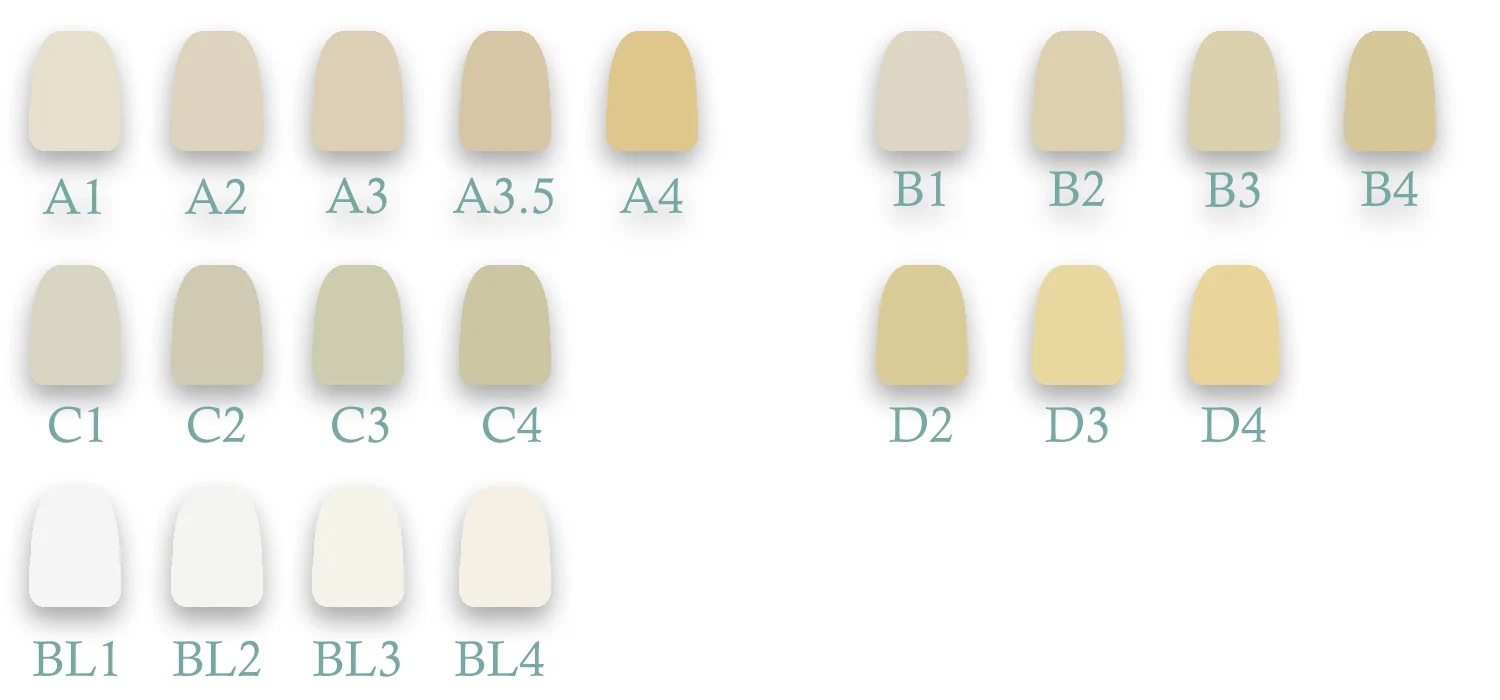

For True-to-Life Anterior Restorations

Color transparency, three-dimensional gradient, natural and close to real teeth.

EXCEPTIONAL AESTHETICS

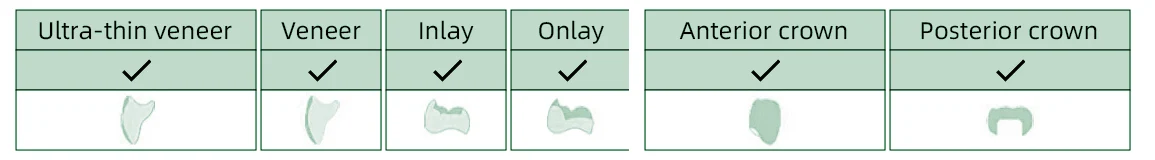

637MPa Flexural Strength: Far Exceeds The Industry Average Of 500-600MPa, Matching The Bending Strength Of Natural Dentin, Making It ldeal For Posterior High Occlusion Restorations.

Ultimate Aesthetics And Minimally Invasive

Simulating the optical properties of natural tooth enamel, with no gray lines on the edges, it is perfectly suitable for aesthetic restoration of anterior teeth.

Complement

| Performance Index | Value/Range | ||

| Coefficient of thermal expansion (25 – 500℃) [10⁻⁶/K⁻¹] | 10.5±0.5 | Chemical solubility [μg/cm²] | <100 |

| Three point bending strength [MPa] | ≥637MPa | Density [g/cm³] | 2.3 – 2.6 |

Sintering curve —— one – stage crystallization process

| Process Stage/Parameter | Specific Content | Process Stage/Parameter | Specific Content |

| starting temperature(℃) | 400 | keep time(min) | 7:00 |

| Drying time(mm: ss) | 0:30 | vacuum begins(℃) | 550 |

| Heating rate(℃/min) | 40 | Vacuum ends(℃) | 835 |

| Maintain temperature(℃) | 835 |

Sintering curve —— Two – stage crystallization procedure

| Process Stage/Parameter | Specific Content | Process Stage/Parameter | Specific Content |

| starting temperature(℃) | 400 | keep time(min) | 00:10/07:00 |

| Drying time(mm: ss) | 6:00 | vacuum begins(℃) | 550/820 |

| Heating rate(℃/min) | 90/30 | Vacuum ends(℃) | 820/835 |

| maintain temperature(℃) | 820/835 |

White Zirconia Blocks

White Zirconia Blocks Multilayer Zirconia Blocks

Multilayer Zirconia Blocks Color Zirconia Blocks

Color Zirconia Blocks 3D Zirconia Blocks

3D Zirconia Blocks 4D Zirconia Blocks

4D Zirconia Blocks Lithium Disilicate

Lithium Disilicate Amber Lithium Disilicate

Amber Lithium Disilicate Press Porcelain

Press Porcelain WAX Disc

WAX Disc Dental PMMA Disc

Dental PMMA Disc Titanium Discs

Titanium Discs Dental PMMK Disc

Dental PMMK Disc Dental Milling Burs

Dental Milling Burs Stain & Glaze

Stain & Glaze Dental polish kit

Dental polish kit Desktop dental 3D scanners

Desktop dental 3D scanners Intraoral scanner

Intraoral scanner